Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() April 09, 2021

April 09, 2021

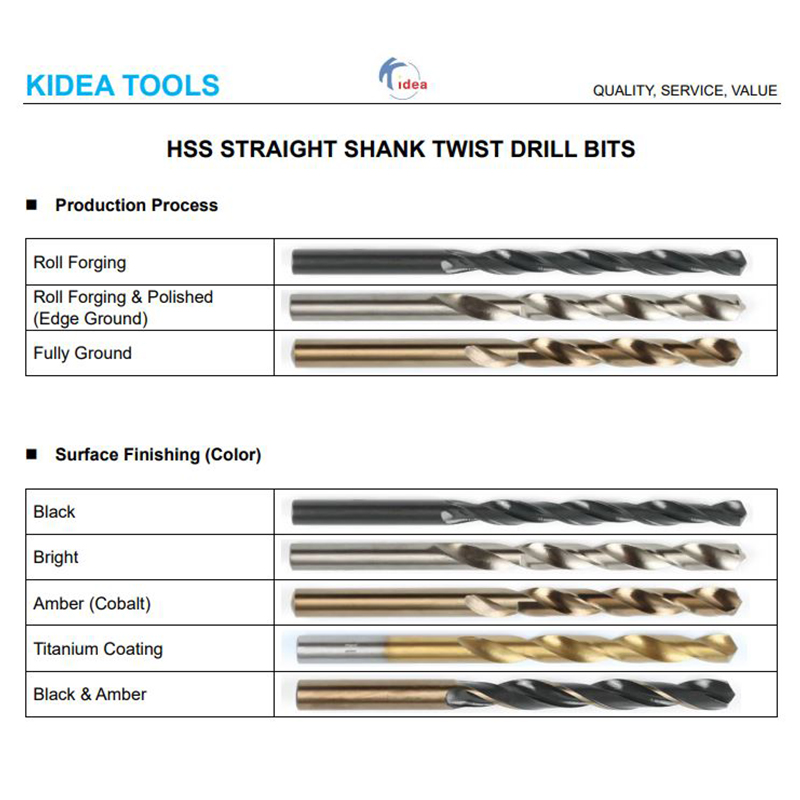

Straight shank Twist Drill is the most widely used hole machining tool. Usually the diameter ranges from 0.25 to 80 mm. It is mainly composed of working part and handle. The working part has two spiral grooves, shaped like a twist, hence the name. Perhaps for those friends who are first exposed to straight shank twist drills, they are not very familiar with straight shank twist drills. Do not worry, if you have needs in this area, may wish to work together with me the knowledge to understand straight shank twist drill at the presentation of it! Maybe it will help you!

Introduction of straight shank twist drill

Straight shank twist drill is the most widely used hole machining tool. Usually the diameter ranges from 0.25 to 80 mm. It is mainly composed of working part and handle. The working part has two spiral grooves, shaped like a twist, hence the name.

Composition of straight shank twist drill

Twist drills can be divided into three parts according to their functions:

1. The part of the drill shank bit for clamping, and used to transmit the power (torque and axial force) required for drilling.

2. The drill neck is located at the transition between the cutter body and the drill shank. It is usually used as an empty slot for retraction of grinding wheels.

3. The working part of the drill bit. It consists of cutting part (ie drill tip) and guide part.

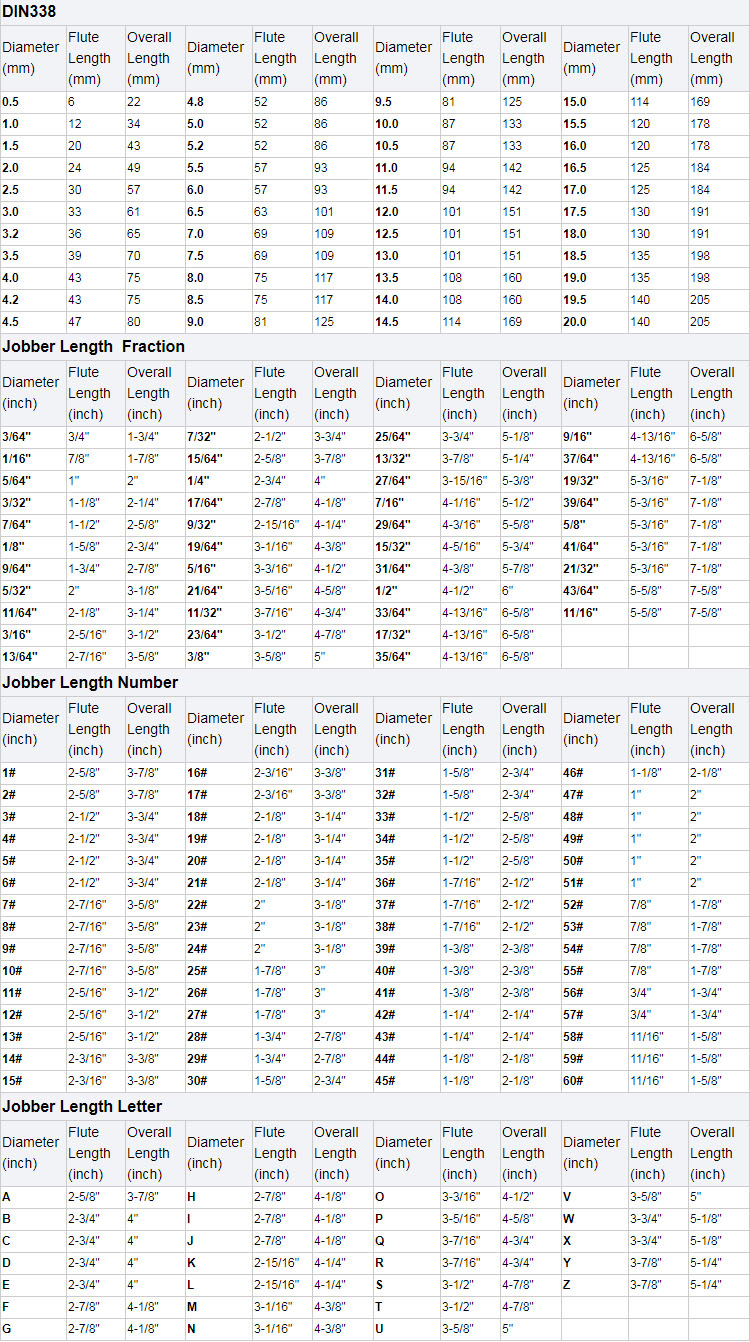

Straight shank twist drill specifications

Straight shank twist drills are generally divided into national standard and American standard, as long as the national standard does not exceed two digits after the decimal point, such as 10.0 ?? 10.2 ?? 10.25. American standard, main specifications 1/8, 9/64, 5/32, 11/64, 3/16, 13/64, 7/32, 15/64, 1/4, 17/64, 9/32, 5 / 16, 21/64, 11/32, 23/64, 3/8, 25/64, 13/32, 27/64, 7/16, 29/64, 15/32, 31/64, 1/2 . In addition, there are some special drills, such as flanging drills, and some non-standard drills produced according to customer requirements!

Straight shank twist drill parameters

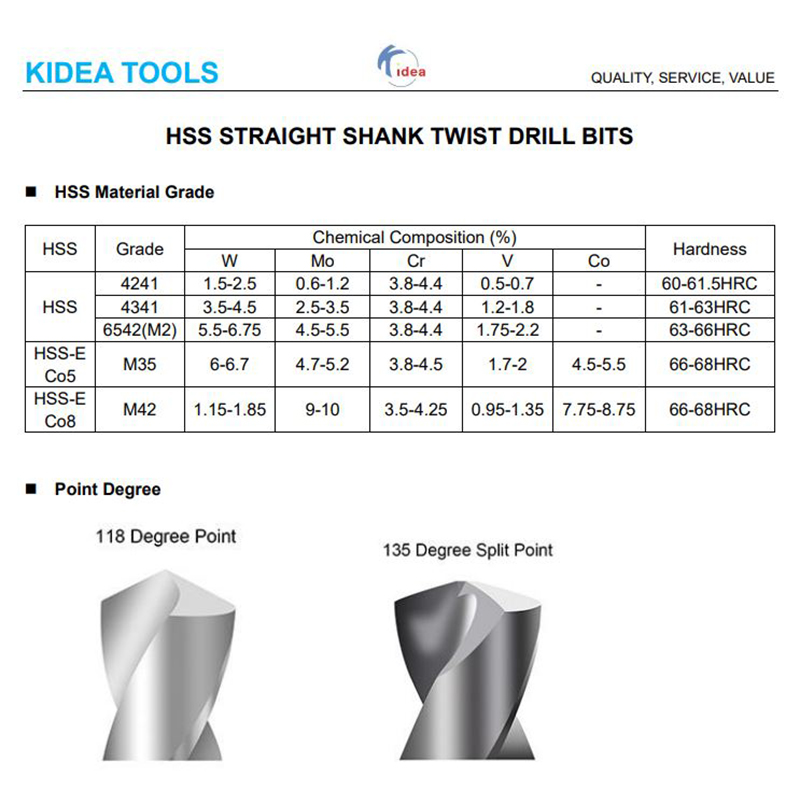

In order to reduce the friction between the guide part and the hole wall when drilling, the Straight Shank Twist Drill Bit gradually decreases in diameter from the drill tip to the shank and assumes an inverted cone shape. The helical angle of a straight shank twist drill mainly affects the size of the rake angle on the cutting edge, the strength of the blade flap and the performance of chip evacuation, usually 25 ° ~ 32 °.

The spiral groove can be processed by milling, grinding, hot rolling or hot extrusion. The front end of the drill bit is sharpened to form a cutting part. The cutting angle of the standard straight shank twist drill is 118, the oblique angle of the transverse blade is 40 ° ~ 60 °, and the relief angle is 8 ° ~ 20 °.

Due to structural reasons, the rake angle is large at the outer edge and gradually decreases toward the middle, and the negative rake angle at the transverse edge (up to about -55 °) acts as a squeeze during drilling. In order to improve the cutting performance of straight shank twist drills, the cutting part can be ground into various shapes (such as group drills) according to the nature of the material to be processed.

Straight shank twist drills have two types of shank: straight shank and tapered shank. During processing, the former is clamped in the drill chuck and the latter is inserted in the taper hole of the machine tool spindle or tailstock. Generally straight shank twist drills are made of high speed steel. Straight shank twist drills with welded carbide blades or crowns are suitable for processing cast iron, hardened steel and non-metallic materials, and solid carbide small straight shank twist drills are used for processing instrument parts and printed circuit boards.

Straight shank twist drill maintenance

1. When drilling steel parts, please ensure sufficient cooling and use metal cutting fluid.

2. Good drill pipe rigidity and guide rail clearance can improve the accuracy of drilling and the life of drill bit.

3. Make sure that the magnetic base and the workpiece are flat and clean.

4. Reinforce the workpiece when drilling thin plates, and ensure the stability of the workpiece when drilling large workpieces.

5. At the beginning and end of drilling, the feed rate should be reduced by 1/3.

6. When drilling, there are a lot of fine powder materials, such as cast iron, cast copper, etc., instead of using cooling liquid, compressed air can be used to help chip removal.

7. Please remove the iron filings wrapped around the drill body in time to ensure smooth chip removal.

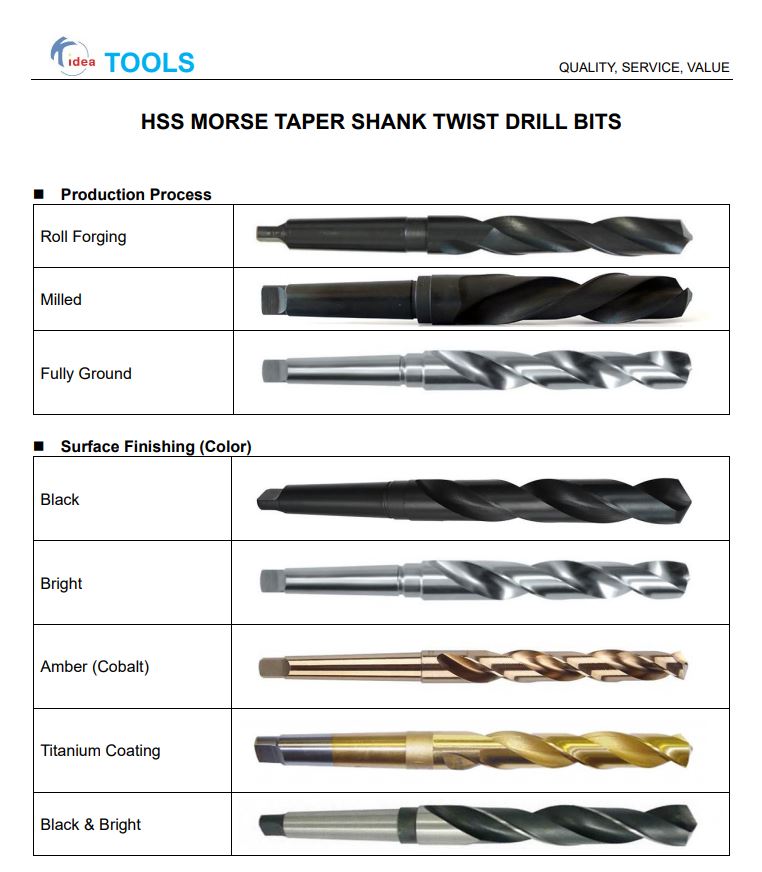

The difference between straight shank twist drill and taper shank twist drill

Generally, taper shank twist drills are used for diameters above 13mm, and straight ones are used for the following. Mainly consider the convenience of clamping and sufficient clamping force. It is obviously not cost-effective to make a small drill bit into a cone, so it is made into a straight shank.

There must be two types of drills equipped with rocker drills. Another complete set of Morse drill sleeves is a must. One drill chuck with No. 3 Morse drill sleeve should also be prepared. The chuck can use 0-13 or 2-16. If it will not drill holes below 1mm, compare with 2-16 drill chuck Good (twist drills with straight shanks, taps, etc.).

The drill chuck must have a specially equipped wrench (usually called a chuck spoon), and the Morse taper sleeve must be equipped with a cone iron, but this thing is generally self-made.

Editor's summary: The above is the introduction about the difference between the straight shank twist drill and the tapered shank twist drill. I hope to help friends who have needs in this regard! For more related information, please continue to follow our website, and more exciting content will be presented in the future. You can also go to Qijia Mall to buy more products you like!

What, the decoration still uses his own money? ! The Qi family is decorated in installments, with an ultra-low annual interest rate of 3.55% and a maximum loan of 1 million. Apply now to enjoy the discount

If you are interested in brand cooperation, content cooperation, and advertising of this website, please send an email to :.

Alloy drill bit water drill bit brand twist drill

The above is the The difference between straight shank twist drill and taper shank twist drill - KIDEA TOOLS we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

Send Inquiry

Send Inquiry

Mr. Kevin ZHU

Email:

Send Inquiry Tel:86-0511-85166018

Fax:86-0511-85166150

Mobile Phone:+8613236358258

Email:

Address:6th Tiangong West Road, Houxiang Town, Danbei Town, Danyang City, Zhenjiang, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.